Service Plans

Maintaining any equipment is important. After all, you made an investment in it when you purchased it and you want to keep it running smoothly so that your production processes also keep moving.

Equipment Maintenance

Maintaining any equipment is important. After all, you made an investment in it when you purchased it and you want to keep it running smoothly so that your production processes also keep moving. You also want it to last as long as possible to get the biggest return you can on your investment.

Proactive preventative maintenance programs (PMP) can help to extend the life of a forklift by addressing problems before they cause significant damage, and by reducing incidents through ensuring that the forklift is operating effectively. It can also improve the value of the asset at retirement.

Internal Combustion

Internal Combustion or IC forklifts are those machines that are fuelled by a fossill fuel such as LPG, Petrol or Diesel. The recommended service intervals for these machines are outlined below. Our service advisors are able to provide competitive pricing and quotes for either individual servicing to completely maintained & managed plans to suit specific or hybrid fleets. A Preventative Maintenance Plan, i.e. regular service is known as a PMP. The timeline for which the services should follow is below:

![]()

The Type A service - PMP Service with replacement of engine oil, engine oil filter, spark plug inspection or replacement (Unless Platinum). Inspect & Adjust Brakes, Steering, Transmission, Drive Line, Mast Functionality, Inspect and Test Electrical system ( Lights etc), Conduct Safety Check & Clean and Grease Unit.

The Type B service - Type A PMP Service with additional air filter & fuel filter (if applicable) and Platinum Plug replacement

The Type C service - PMP Service with replacement of engine oil, engine oil filter, spark plugs (Unless Platinum). Inspect & Adjust Brakes, Steering, Transmission, Drive Line, Mast Functionality, Inspect and Test Electrical system ( Lights etc), Conduct Safety Check & Clean and Grease Unit.

The Type D service - Type B PMP Service with all additional filters & oils replaced including transmission oil & filters and hydraulic filter. Location - workshop

The Type E service - Type D PMP Service including replacement of hydraulic oil. Location - workshop.

Type D & E Services would also include a comprehensive report detailing any excessively worn parts (Brakes, Tyres, Forks and carriage components). This would be predominantly a workshop service due to all oils and time to complete.

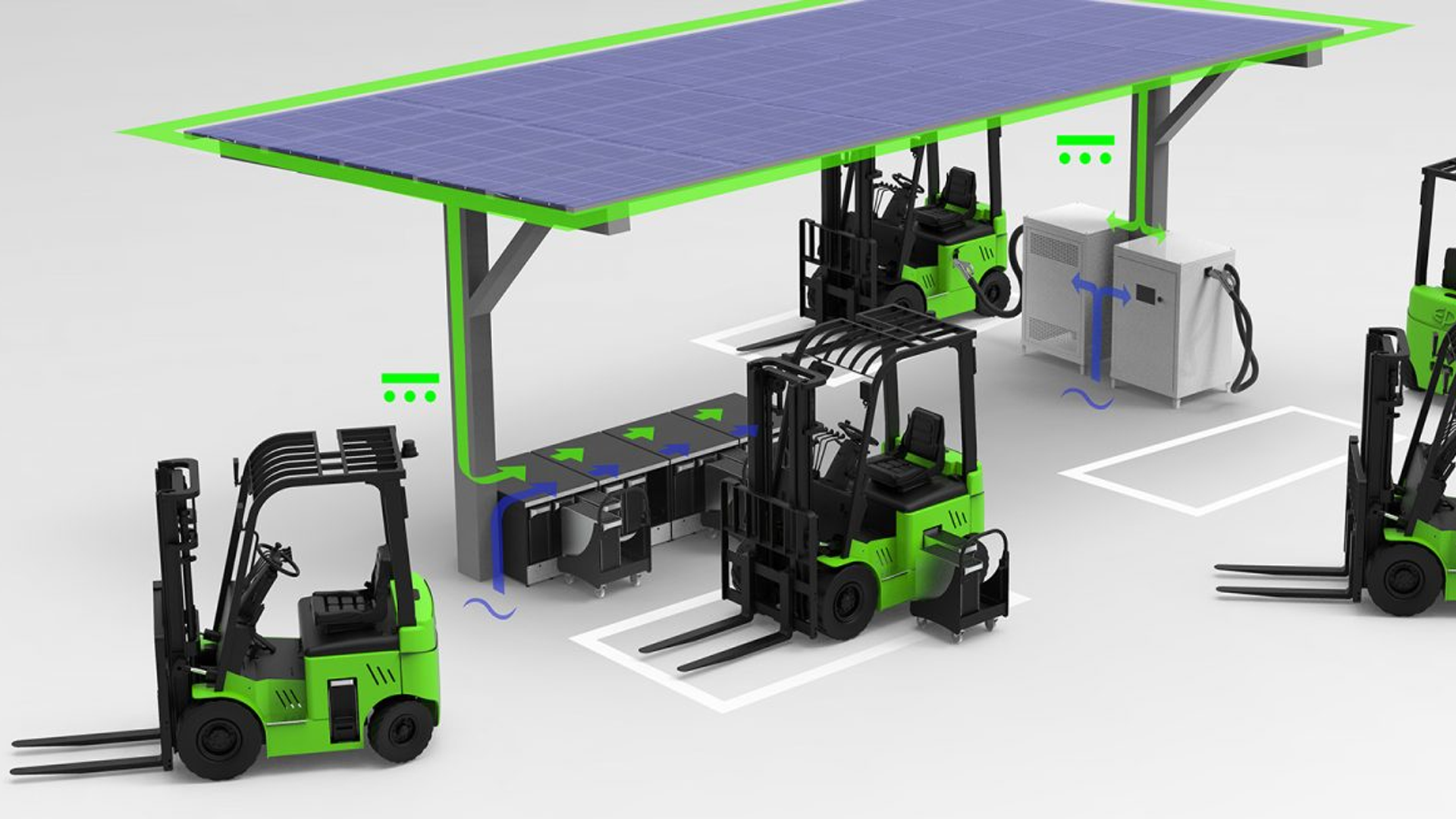

Battery Electric

Battery electric or BE forklifts are those machines that are fuelled by an electric fuel source, typically a battery. The recommended service intervals for these machines are outlined below. Our service advisors are able to provide competitive pricing and quotes for either individual servicing to completely maintained & managed plans to suit specific or hybrid fleets. A Preventative Maintenance Plan, i.e. regular service is known as a PMP. The timeline for which the services should follow is below:

![]()

The Type A service - PMP Service with com stick motors, clean contact tips, check battery water level.

The Type B service - PMP Service with com stick motors, clean contact tips, check battery water level.

The Type C service - PMP Service with com stick motors, clean contact tips, check battery water level.

The Type D service - Type A PMP Service with battery acid adjustment and replacement of hydraulic oil filter. Location - workshop

The Type E service - Type D PMP Service including replacement of hydraulic oil. Location - workshop.

Type D & E Services would also include a comprehensive report detailing any excessively worn parts (Brakes, Tyres, Forks and carriage components). This would be predominantly a workshop service due to all oils and time to complete.