Seasonal Forklift Maintenance: Preparing for Peak Performance

Understanding the Importance of Seasonal Forklift Maintenance

As the seasons change, so do the demands placed on your forklift fleet. Ensuring that your forklifts are in peak condition is crucial for maximizing efficiency and safety in your operations. Regular maintenance not only extends the lifespan of your equipment but also prevents costly downtime.

Seasonal maintenance involves a thorough inspection and servicing of various parts of the forklift. This proactive approach helps identify potential issues before they escalate, ensuring your equipment performs optimally during peak seasons. It's essential to tailor your maintenance routine to address seasonal challenges.

Spring: Preparing for Increased Activity

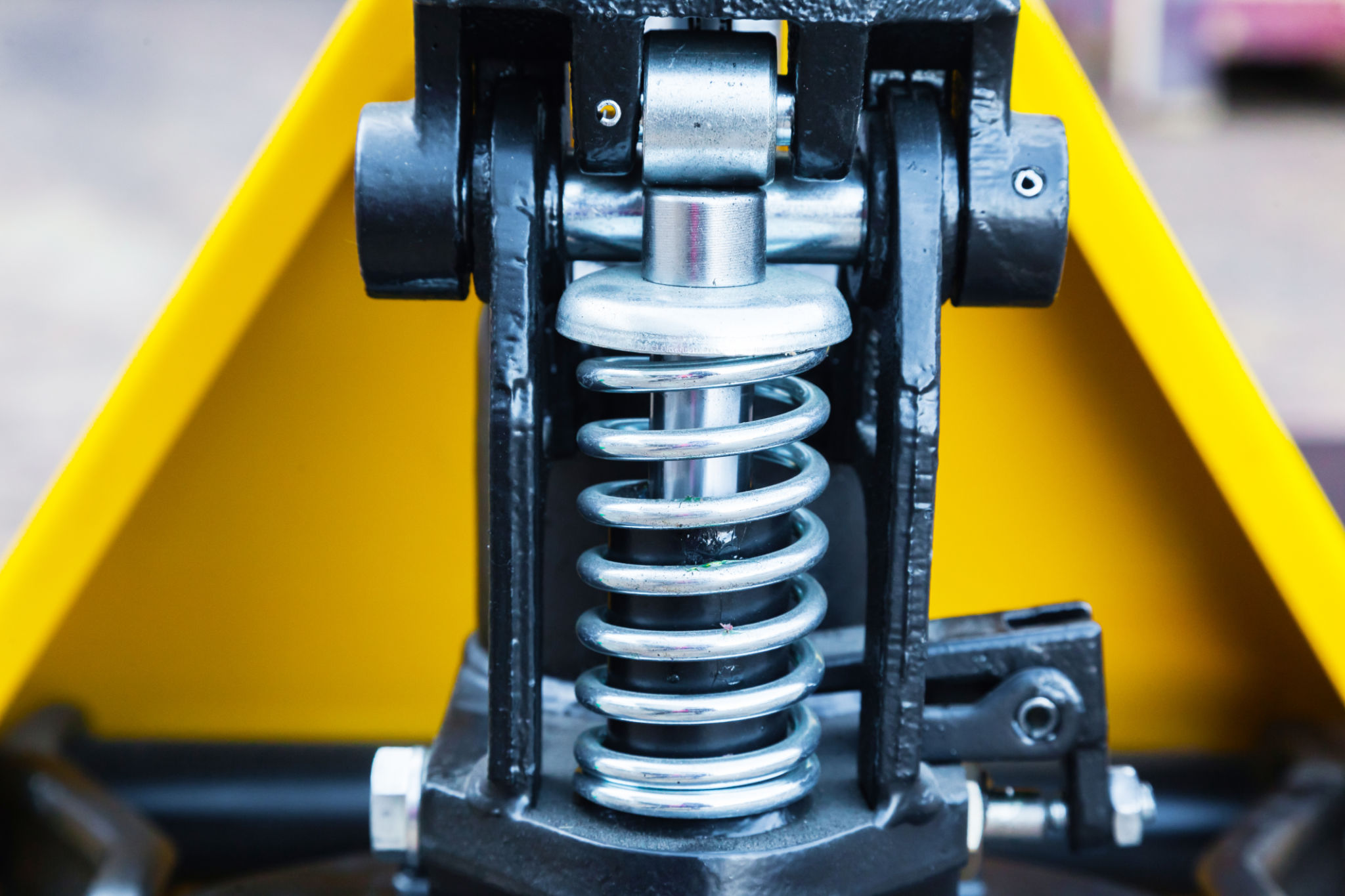

Spring often signals a ramp-up in business activities. As you prepare for increased workload, focus on inspecting the hydraulic systems and replacing any worn-out hoses or seals that may have suffered during the winter months. Pay attention to the forklift's battery, as fluctuating temperatures can impact its performance.

Additionally, it's wise to check the tires for wear and adjust tire pressure to accommodate warmer weather. A comprehensive spring maintenance routine ensures your forklifts are ready to handle the demands of a busy season without interruptions.

Summer: Keeping Your Equipment Cool

Summer heat can put additional stress on your forklifts, especially on cooling systems. Make sure radiators are clean and functioning correctly to prevent overheating. It's also crucial to check and maintain fluid levels, including engine oil and coolant, to keep equipment running smoothly.

Regularly inspect and clean air filters to ensure adequate airflow and prevent engine strain. By focusing on these areas, you maintain high performance and reduce the risk of unexpected breakdowns during peak summer operations.

Fall: Preparing for Colder Temperatures

As temperatures begin to drop, it's time to prepare your forklifts for colder conditions. Inspecting and servicing the engine's heating system will ensure operators remain comfortable and productive. Additionally, examining the battery's condition is essential, as cold weather can reduce battery efficiency.

Consider switching to winter-grade lubricants that perform better in lower temperatures. This switch can significantly enhance the reliability of your forklifts in colder climates. Proper fall maintenance sets the stage for a smooth transition into winter operations.

Winter: Ensuring Reliability in Harsh Conditions

Winter poses unique challenges such as freezing temperatures and slippery surfaces. Prepare your forklifts by ensuring all lights are functioning correctly for optimal visibility. It's also important to regularly check tire tread and consider using tire chains if necessary.

Conduct a thorough inspection of the braking system, as it plays a critical role in maintaining safety during icy conditions. Keeping these components in top shape helps prevent accidents and maintains operational efficiency throughout the winter months.

Creating a Year-Round Maintenance Schedule

Developing a year-round maintenance schedule is key to ensuring your forklifts are always ready for action. Collaborate with your maintenance team to create a detailed plan that includes regular inspections, servicing, and component replacements tailored to each season's unique demands.

By following a structured maintenance routine, you not only enhance the performance of your forklift fleet but also safeguard against unexpected expenses. Remember, proactive care is crucial for achieving peak performance throughout the year.